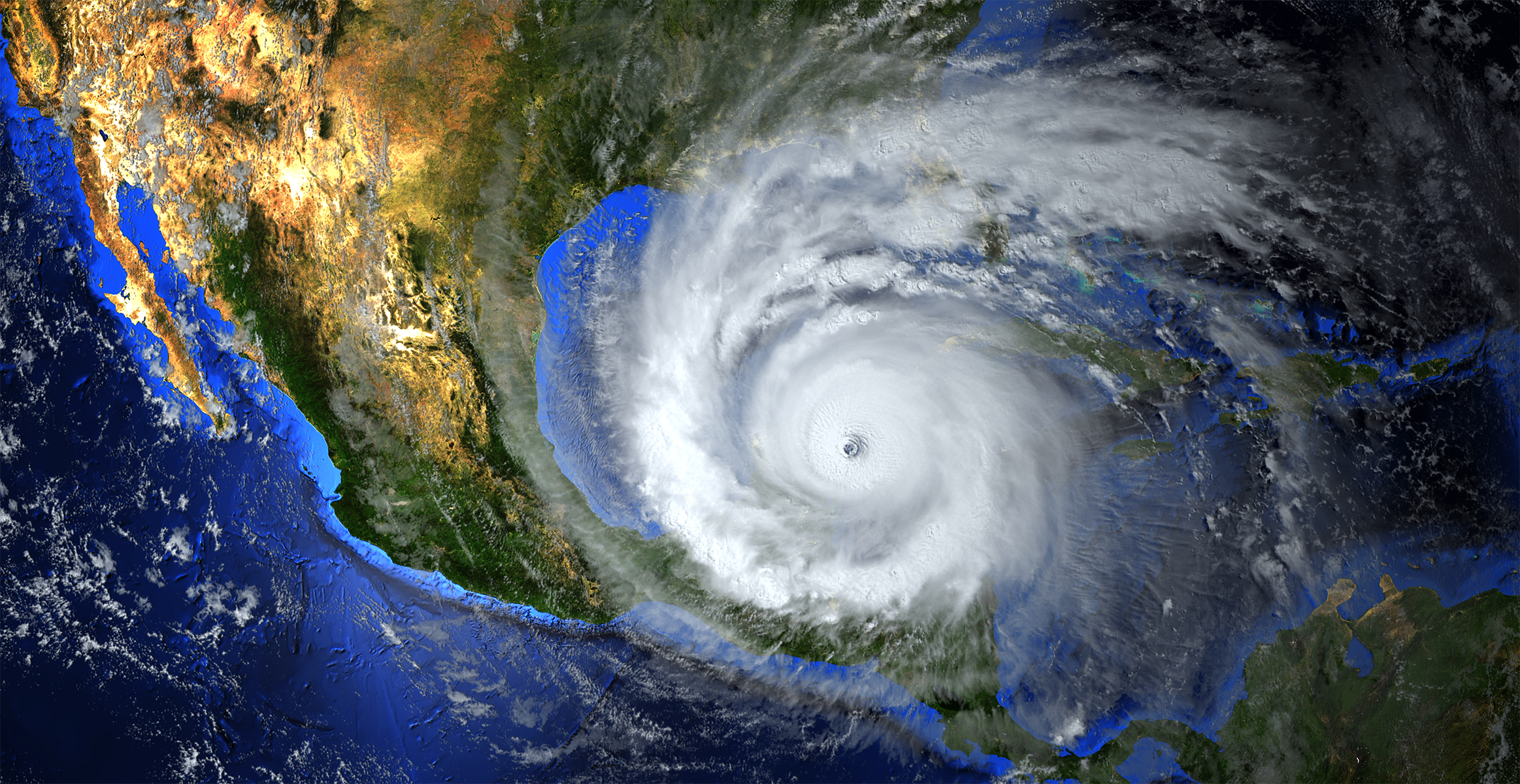

Hurricane Helene’s devastating impact on North Carolina and the broader Appalachian region has led to a crisis that reaches far beyond storm damage. Flooding and infrastructure damage forced a temporary halt in IV fluid production at Baxter’s North Cove facility in North Carolina, a plant supplying approximately 60% of the nation’s IV fluids. With the loss of such a critical production hub, hospitals and emergency departments are now navigating significant shortages in IV fluids, an essential treatment resource for dehydration, surgical support, and emergency care.

The Scope of the Shortage

According to an analysis by Truveta Research, IV fluid administration in emergency rooms dropped substantially since Hurricane Helene’s landfall. In pre-storm conditions, an average of 6.6% of ER patients admitted for dehydration received saline IV treatments. However, just ten days post-storm, this rate plummeted to 2.5%, revealing a marked decrease in available supplies. The trend was consistent across age groups, with similar declines for patients experiencing nausea or vomiting.

IV fluids are not only used for hydration but also serve critical functions in surgeries, trauma care, and chronic illness management. Without a reliable supply, hospitals must rapidly adapt their protocols to manage existing resources. For some patients, oral alternatives like electrolyte-rich drinks can suffice, but for many—especially those undergoing surgeries or treatment for severe illnesses—IV fluids are indispensable.

IV fluids are not only used for hydration but also serve critical functions in surgeries, trauma care, and chronic illness management. Without a reliable supply, hospitals must rapidly adapt their protocols to manage existing resources. For some patients, oral alternatives like electrolyte-rich drinks can suffice, but for many—especially those undergoing surgeries or treatment for severe illnesses—IV fluids are indispensable.

Emergency Measures to Address the Shortage

In response, the U.S. Department of Health and Human Services (HHS) invoked the Defense Production Act to support Baxter International in reestablishing production. This federal intervention allows for prioritizing essential resources, helping expedite recovery efforts at the North Cove facility. Meanwhile, the FDA extended expiration dates on certain IV fluid stocks and permitted temporary importation from foreign manufacturers to alleviate immediate demand pressures. Other U.S.-based manufacturers, such as B. Braun Medical and ICU Medical, have also ramped up production to bridge the supply gap.

The Centers for Disease Control and Prevention (CDC) and other health agencies have released guidelines to conserve IV fluid supplies. Recommendations include assessing clinical needs carefully, substituting with oral hydration solutions when possible, and prioritizing IV use strictly for cases where alternatives aren’t viable.

The Centers for Disease Control and Prevention (CDC) and other health agencies have released guidelines to conserve IV fluid supplies. Recommendations include assessing clinical needs carefully, substituting with oral hydration solutions when possible, and prioritizing IV use strictly for cases where alternatives aren’t viable.

Command Centers and Real-Time Decision-Making

To manage the crisis effectively, many hospitals have activated command centers, ensuring continuous monitoring and allocation of limited IV supplies. These command centers are also preparing for potential complications arising from respiratory virus season, where patients with severe respiratory conditions often require IV fluids due to an inability to take medications orally.

Even as Baxter resumes some level of manufacturing, the supply chain’s recovery will take time. The company anticipates a phased return to full production capacity, with shipments expected to reach healthcare providers incrementally over the coming weeks. To keep healthcare operations running efficiently in the interim, command centers are focused on short-term strategies, conserving what resources they have while awaiting additional shipments.

Even as Baxter resumes some level of manufacturing, the supply chain’s recovery will take time. The company anticipates a phased return to full production capacity, with shipments expected to reach healthcare providers incrementally over the coming weeks. To keep healthcare operations running efficiently in the interim, command centers are focused on short-term strategies, conserving what resources they have while awaiting additional shipments.

The Role of Data and Resource Optimization in Crisis Management

The shortage highlights the importance of data-driven resource management. The healthcare sector’s shift to digital record-keeping and real-time data analysis has enabled organizations like Truveta Research to quickly assess the crisis and project demand, guiding federal and industry responses. Digital health record platforms allow for timely analysis, identifying trends in IV fluid usage that inform conservation strategies and help healthcare providers make data-informed decisions under pressure.

Looking Ahead: Preparedness for Future Shortages

While the IV fluid shortage remains acute, federal agencies and private manufacturers are leveraging every available tool to restore supplies. Hurricane Helene’s impact underscores the importance of resilient supply chains and the need for emergency preparedness, especially within the healthcare system. Moving forward, lessons learned from this crisis may drive policy changes to bolster domestic production capabilities and create more robust contingency plans.

For now, the healthcare community remains focused on adapting to current limitations, leveraging command centers and efficient supply management practices to support patient care. As IV fluid production resumes, these measures will help ensure that the most vulnerable patients receive the care they need until full inventory can be restored across the U.S.

For now, the healthcare community remains focused on adapting to current limitations, leveraging command centers and efficient supply management practices to support patient care. As IV fluid production resumes, these measures will help ensure that the most vulnerable patients receive the care they need until full inventory can be restored across the U.S.

Leveraging Juvare’s WebEOC, Crisis Track, and EMResource in Supply Chain Crises

In response to crises like the IV fluid shortage, Juvare’s suite of emergency management solutions offers healthcare systems critical tools for resource management, communication, and coordination.

WebEOCserves as a centralized platform that enables hospitals, emergency departments, and public health agencies to share real-time information and collaborate on resource allocation. By centralizing incident management, WebEOC ensures that facilities facing critical shortages can coordinate seamlessly with local and federal agencies for support and resource sharing.

Crisis Trackfurther enhances these efforts by providing detailed tracking and reporting capabilities that aid in assessing disaster-related impacts on healthcare facilities. This tool is essential for tracking damages to infrastructure like Baxter’s North Cove plant, providing the insights necessary for rapid decision-making and recovery planning. For facilities impacted by Hurricane Helene, Crisis Track assists in managing asset damage reports and tracking restoration progress.

Finally, EMResource plays a vital role in the ongoing management of healthcare assets. With visibility into supplies, bed availability, and staffing resources across connected facilities, EMResource helps allocate available IV fluid supplies and other critical resources where they are needed most. It allows for real-time updates, so healthcare providers can make data-informed decisions and respond effectively as new shipments of IV fluids arrive.

WebEOCserves as a centralized platform that enables hospitals, emergency departments, and public health agencies to share real-time information and collaborate on resource allocation. By centralizing incident management, WebEOC ensures that facilities facing critical shortages can coordinate seamlessly with local and federal agencies for support and resource sharing.

Crisis Trackfurther enhances these efforts by providing detailed tracking and reporting capabilities that aid in assessing disaster-related impacts on healthcare facilities. This tool is essential for tracking damages to infrastructure like Baxter’s North Cove plant, providing the insights necessary for rapid decision-making and recovery planning. For facilities impacted by Hurricane Helene, Crisis Track assists in managing asset damage reports and tracking restoration progress.

Finally, EMResource plays a vital role in the ongoing management of healthcare assets. With visibility into supplies, bed availability, and staffing resources across connected facilities, EMResource helps allocate available IV fluid supplies and other critical resources where they are needed most. It allows for real-time updates, so healthcare providers can make data-informed decisions and respond effectively as new shipments of IV fluids arrive.